Punjab Man Uses Straw to Make Eco Fuel

Meet Sukhmeet Singh, the man who is solving the nation’s paddy straw burning problem with this national award-winning startup, A2P (Agri2Power) Energy Solution.

Did you know that India produces more than 550 million tonnes of crop residue every year, and that the highest producers of this crop residue are Uttar Pradesh, Punjab, and Haryana?

Ever wonder what happens to most of this agricultural waste? Well, in the absence of space to hoard this residue or alternative methods to dispose of it, the average farmer takes the cheapest route—he sets this stubble on fire. The smoke from this straw burning is one of the leading reasons smog and heavy pollution in the national capital, Delhi.

But one man wants to change this.

Meet Sukhmeet Singh, the man who is solving the nation’s paddy straw burning problem with his national award-winning startup, A2P (Agri2Power) Energy Solution.

Established in March 2018, A2P Energy Solution is working with farmers by buying off this crop residue from them and converting this waste to useful products for the energy sector.

In an exclusive interview with The Better India, Sukhmeet narrates his journey.

As a technology consultant, Singh worked for industry biggies like TCS, Satyam and Tech Mahendra and in countries like the US, UK and Dubai.

In 2011, he started working as an Associate Director with (his alma mater) Indian School of Business’ Entrepreneurship cell at the Hyderabad campus. He soon moved to Mohali and helped set up ISB’s Mohali campus and started working with the Government on areas of Public Policy, Agriculture and Cold Supply.

He played a key role in getting the Atal Incubator at the school’s Mohali Campus.

“I was working on a project with UK-based Aston University to understand the leading issues that plagued the agricultural sector in India, especially Punjab, and was shocked at the environmental issues caused by stubble burning every year,” he says.

These are some of the highlights of the research that Singh conducted to understand the impact of stubble burning in North India:

.Every year 35 million tonnes of straw is produced in northern India in September and October alone and most of it is burned.

.A direct consequence of this is visible in cities such as New Delhi which ranked as having the worst air quality in the world in 2018.

.The air in Delhi consists of 20 times more polluting particles than the World Health Organization recommends.

.The economic and health costs to tackle this are estimated to be $30 billion in a single season. This amount is 1.5 times the Indian budget for health and education.

“In Punjab itself, there is more than 20 million tonnes of paddy straw that needs to be managed before a new cropping season starts. This window is hardly three weeks and the farmers don’t have too many options. The government fines them for burning straw, they cannot push the residue back into the soil because it increases the chance of pest attacks and they also need new and bigger machinery for that. Additionally, most of them have restricted space on their farms, so hoarding isn’t an option. So, it is their helplessness that pushes them to burn the straw. What else can they do?”

And therefore Singh’s vision was to create a model that would:

1) Educate and convince farmers to not burn straw

2) Give them additional income by buying it off them

3) And use the paddy straw to produce high-value products for the energy industry.

When Singh quit his job at the Indian School of Business to establish A2P Energy Solution, his family was shocked.

“I was at a senior position at ISB. It was one of the best jobs anyone could have. So my family was apprehensive at the beginning. But with the response we received from stakeholders, the market, farmers and the entire ecosystem in the last one year, they are more supportive than ever.”

The whole process of straw collection and processing is a challenging task at every stage right from convincing farmers to not burn to collecting the straw and processing it. Paddy straw is very abrasive on machines and there are no standard machines available for its processing. These challenges make it a daunting task for anybody who wants to enter this field.

At a time when nobody thought a startup company like A2P could create a dent in the system, Aston University and Oglesby Charitable Trust were instrumental in providing Singh the support he required.

Products

After extensive research on the issue, Singh and his team began working on the products that could be developed using paddy straw.

They processed this straw to develop pellets or bio-fuel that could be an alternative to coal and wood. The first stage of making the pellets is wholly commercialised, and they have supplied pellets to clients in food processing, pharmaceutical and dyeing industries including Pepsi and Hindustan Unilever.

Since the collection window for the straw was limited, they used several innovations to ensure they managed the collection of the straw.

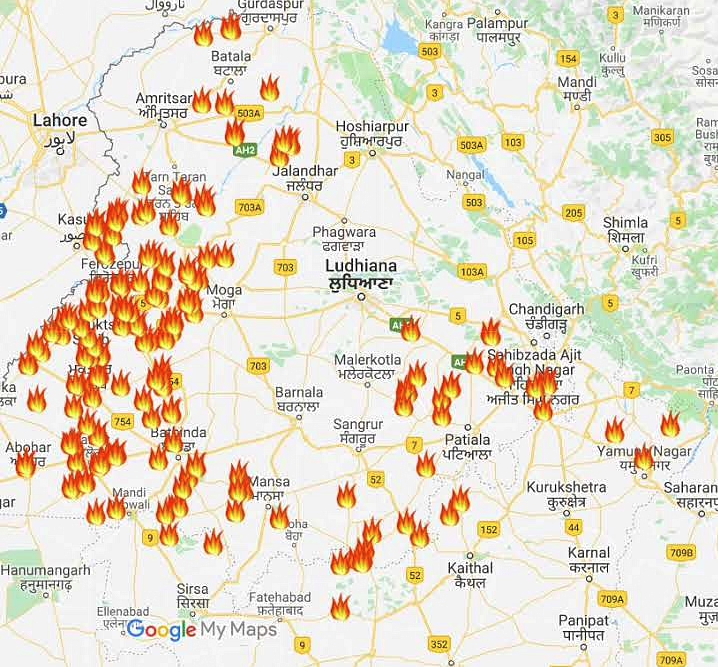

They use advanced machine learning to optimise their operations and track farm fires.

Since the collected straw needs to be transported to their manufacturing plant within 20 days to be effectively converted to biomass fuel, A2P Energy Solution efficiently uses Google map API to extract the images of paddy fields which are close to the harvesting season. This helps them reach out to those farmers, buy that straw and prevent burning.

Similarly, they also use NASA satellite data to track open field paddy straw burning. This helps them single-out crop burning areas and train farmers for paddy straw collection instead of burning.

“We were able to replace conventional fuel. The carbon emissions that we prevented from entering the atmosphere accounts for that emitted by 285 cars on the road every day. In the process of straw collection, we also created entrepreneurs in the village to help us with the straw collection by providing them with customised machines to facilitate the process and creating a system to buy back the straw. During one season of collection, we employ more than 30 people.”

The company did not stop at producing fuel. In a matter of months, they began using the straw to create boards that could be used to build furniture.

Now incubated at the Indian Agricultural Research Institute (New Delhi), they are exploring the technology of producing biochar from straw.

They are also working with Punjab Agriculture University and Indian Institute of Petroleum to explore using pellets either as a soil conditioner or to extract oil out of pellets and use it as furnace oil.

Impact

The company could have easily opted to collect the paddy straw free of cost. But because they wanted to create a value chain where all stakeholders get paid, the farmers earn up to Rs 3000 per acre for straw. This means for an average farmer with 10 acres of land, just collection of straw can generate additional income to the tune of Rs 30,000.

They are currently working with more than 45 farmer families and preventing paddy straw burning on 450 acres of land.

Till date, A2P Energy Solution has saved 900 tonnes of straw from burning.

“There is a huge demand and market for the model that we are working on. Today, we get calls from farmers across India. We now aim to scale this model up and reach out to as many farmers as we can and create high-value products from straw.”

Awards and Recognition

One of the biggest recognitions for the company was winning the first prize at the Startup India challenge for using data and technology to solve social problems.

They competed with more than 522 companies across 34 industry verticals to clinch the honour and won a cash prize of 10 lakh.

They also won the Global Prosperity Award at the Global Manufacturing and Industrialisation Summit in Russia. Besides winning a cash prize of 100,000 USD, they were declared the most innovative entry under the sustainable energy category.

Here, they competed with 1,180 companies across 83 countries and were shortlisted through multiple rounds where they presented the project in Abu Dhabi, Dubai, the University of Cambridge and Russia.

Challenges

The model that A2P Energy Solution has created is capital-intensive. So scaling up is one of the major challenges since they are grappling with funding. They haven’t received any funding from the state or the central Government yet.

“One A2P plant to process straw can cater to three villages. As of now, we do not have any funding support from the Government. One of the other challenges that we are grappling with is that the Government is planning to spend 250 crores on providing farmers with the machinery to put the crop residue back into the soil. Even if a part of this funding was given to us, we could help tackle the issue,” he signs off.

The above text and pictures are from The better India